Energy use in the steel industry Fact sheet World crude steel production reached 1,860 million tonnes in 2020. Steel use is projected to increase steadily in the coming years to meet the needs of our growing population. Energy use in steelmaking

.jpg)

Energy use in the steel industry Fact sheet World crude steel production reached 1,860 million tonnes in 2020. Steel use is projected to increase steadily in the coming years to meet the needs of our growing population. Energy use in steelmaking

.jpg)

2.1 Electric arc furnace In steel industry, integrated steel mill and electric arc furnace (EAF), referred to as mini-mill, are two steel production routes. In integrated mill, iron ore is the primary raw material which is charged to blast furnace (BF), whereas mini-mill is

.jpg)

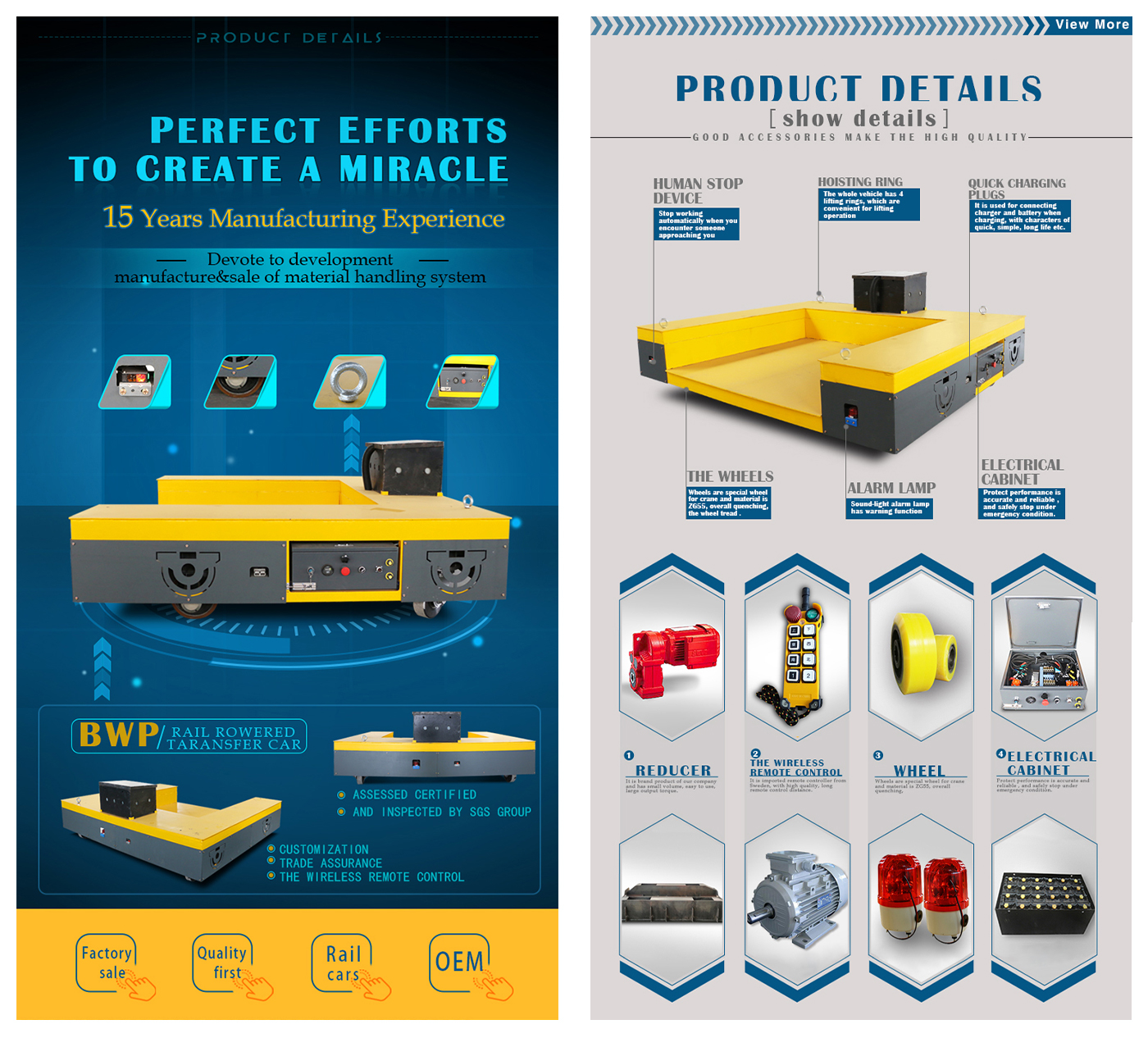

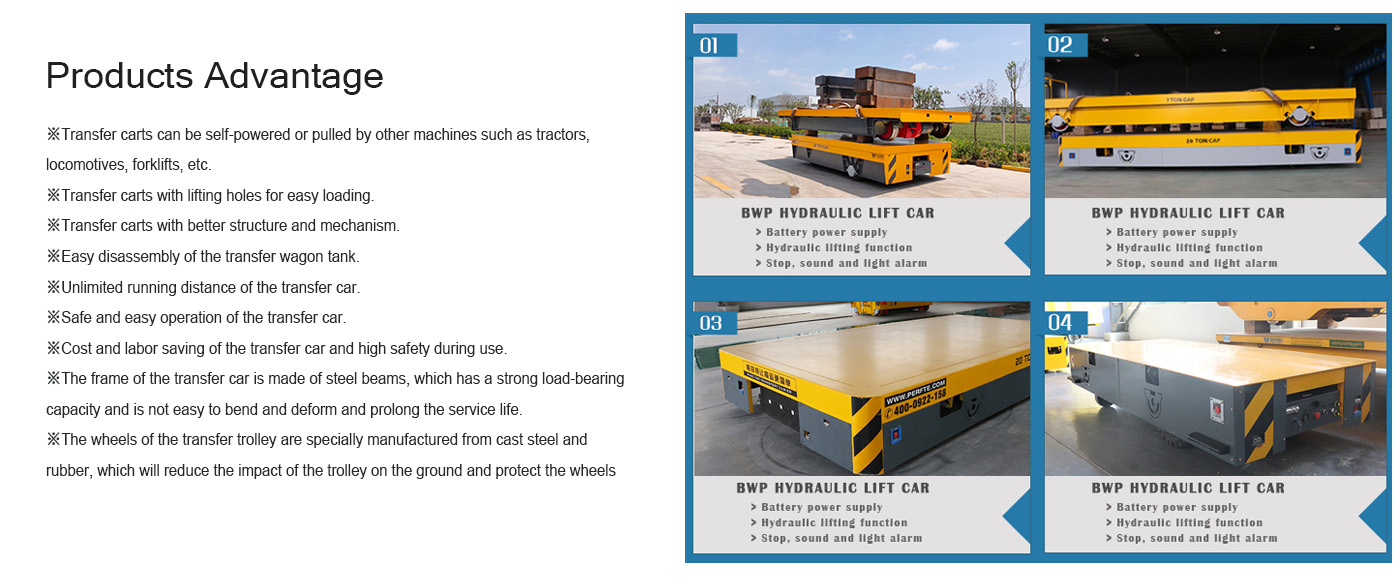

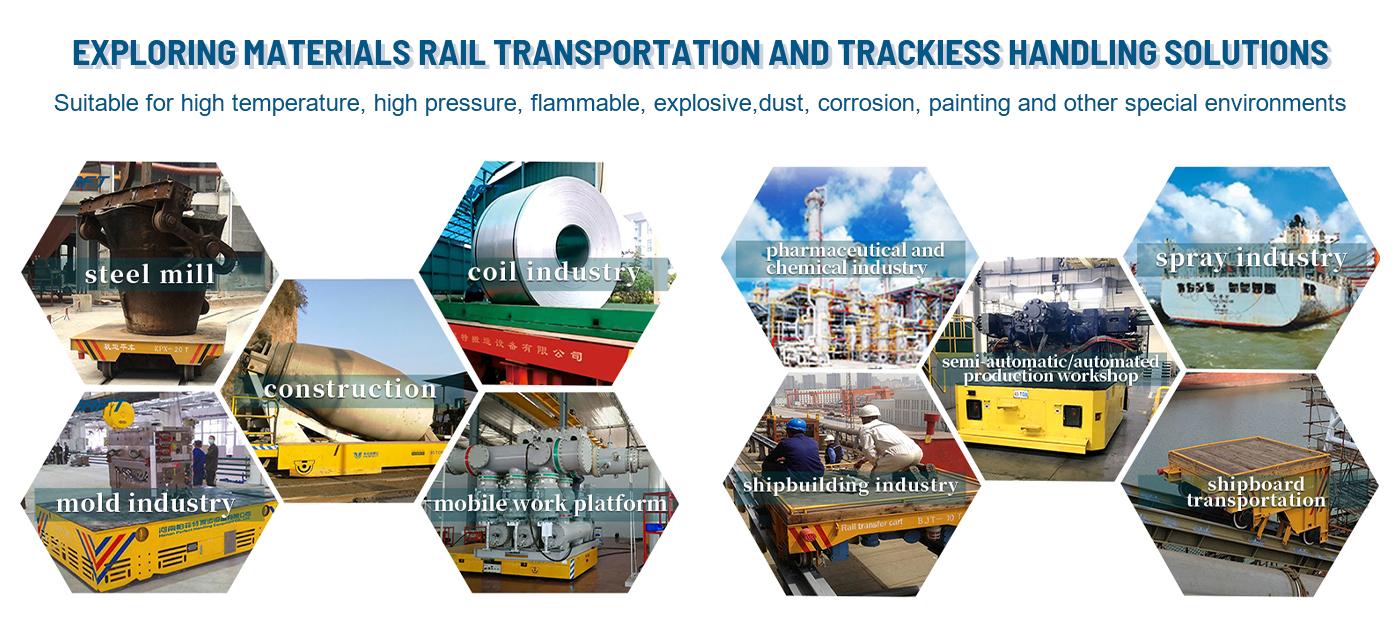

steel pipe transfer trolley is battery powered transfer trol High temperature explosion-proof aluminum tra. High temperature explosion-proof aluminum transfer ladle car... 4 Whels 2 Ton tractor towed Platform battery. industrial trailer platform transfer cart powered by tractor...

.jpg)

As electric vehicles become more commonplace and battery efficiencies improve, use of advanced grades of steel enable reduced weight resulting in a greater range from a single electrical charge. The American steel industry, working with its auto industry partners, continues to revolutionize the safety and durability of cars, while reducing environmental impacts.

.jpg)

History of Galvanized Steel in the Automotive Industry | National Material Company - Steel Processing Facilities. Galvanized steel is among the most popular and ubiquitous steels due to its durability, cost effectiveness, and rust-resistant qualities. Learn how galvanized steel became one of the most widespread steels today.

.jpg)

steel factory apply transfer carts for steel parts transport.. The transfer carts platform structure is the steel beam box .. more machinery parts electric flat transfer carts on rails

.jpg)

Automated Rail Transfer Truck with Warning Light. FOB Price: US $6,000-6,500 / Piece. Min. Order: 1 Piece. Contact Now. Video. 100 Ton Capacity Aluminum Coil Transfer Cart for Steel Industry. FOB Price: US $4,500-4,800 / Piece. Min. Order: 1 Piece. Contact Now.

.jpg)

2/8/2017 · Glencore will get a boost as rising electric-vehicle sales lend support to copper prices, as well as from its position as the world’sPerfectst cobalt producer, according to Jefferies Group LLC.

.jpg)

12.5.1.5 Steelmaking Process — Electric Arc Furnace - Electric arc furnaces (EAF) are used to produce carbon and alloy steels. The input material to an EAF is typically 100 percent scrap. Cylindrical, refractory lined EAFs are equipped with carbon

.jpg)

29/11/2009 · ORE TRANSFER CAR - Part 1. I finally was able to find a copy of plans for the ore transfer cars at Bethlehem Steel. I had considered building it off the photos, however, it is a bit more complicated than it would first appear so I am happy to have the plans. I printed the plans out on 11x17 paper to as close to HO scale as I could.

.jpg)

17/4/2018 · Steel fights back Tesla, global leading producer of EV-s, after two aluminium intensive models (Tesla Model S and Tesla Model X), has launched its smallest and cheapest model so far, Tesla Model 3, which is a steel intensive vehicle (or a “mix of materials”, as Tesla puts it).

.jpg)

30T Electric Transfer Cart for Heavy Industry About the material handling battery transfer car, it is a kind of portable device with multiple functions. It is widely used for transporting material in factory, warehouse, workshop, construction site. It has flexible move, fast

.jpg)

2.1 Electric arc furnace In steel industry, integrated steel mill and electric arc furnace (EAF), referred to as mini-mill, are two steel production routes. In integrated mill, iron ore is the primary raw material which is charged to blast furnace (BF), whereas mini-mill is

.jpg)

4x SPMT of 100 tons each (total 400 TONS) electric power for handling shipbuilding blocks. 30 tons AGV with slam navigation for handling coils from indoors to outdoors for long distances. Die cart 12 tons including push pull system. 80 tons diesel transporter for handling steelmill components.

.jpg)

To meet capacity demands in 2030, organisations need to invest now in factories, tooling, design, innovation and talent. Getting these projections wrong, even at this early stage, could cost manufacturers significant amounts of money. Figure 6. Electric vehicle production forecast of …