Steel Industry Apply Transfer Carts The motorized molten metal ladle transfer car is specially d..more. ... 0.25-20 tons electric wire rope hoist supplier.

.jpg)

Steel Industry Apply Transfer Carts The motorized molten metal ladle transfer car is specially d..more. ... 0.25-20 tons electric wire rope hoist supplier.

.jpg)

Sheet Metal Panels for a Car Body Sheet metal is a major part of an automobile. There are 40 to 50 major panels required for a typical vehicle and are most often produced by the car manufacturer because they define the geometry and quality of the vehicle. It takes 150 to 250 die sets to produce these major body panels.

.jpg)

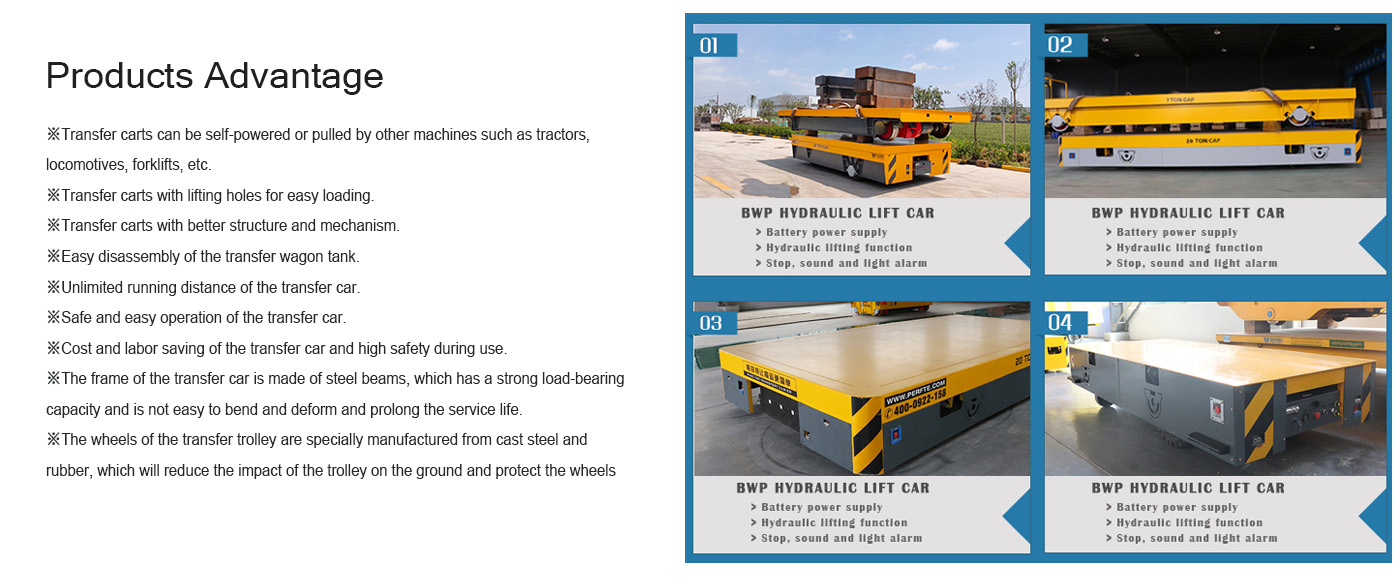

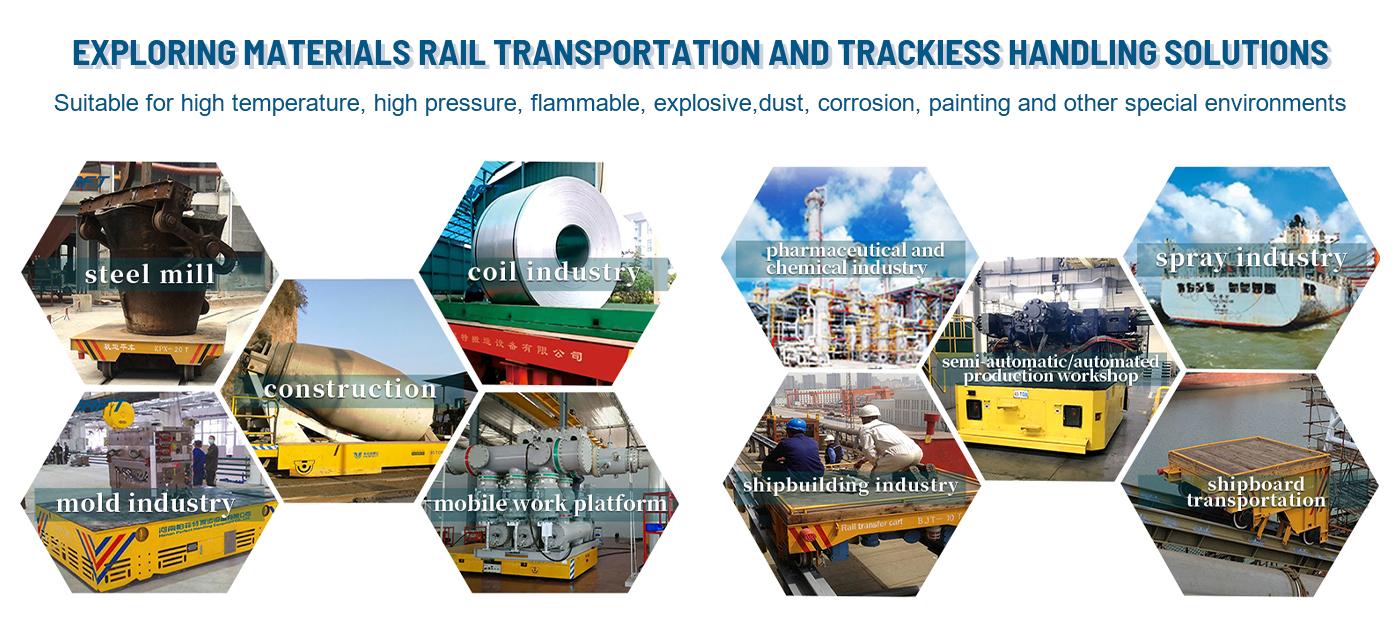

The electric transfer cart can be applied in the occasion with any loading capacity and high using frequency. Electric transfer cart can be used in many places, such as mould field, car field, steel, iron, heavy industry, light industry, chemical, mine, ship, project, spaceflight, coal, nuclear energy, hydraulic engineering,etc.

.jpg)

Jun 25, 2020 · In the manufacturing process, electric vehicles will produce more global warming emissions than the average gasoline vehicle, because electric cars’Perfect lithium-ion batteries require a lot of materials and energy to build. (For example, manufacturing a mid-sized electric car with an 84-mile range, results in 15% more emissions.)

.jpg)

Metallurgy industry: With the functions of steady traveling, stepless speed regulation, the cart is commonly applied to transfer steel ladle, aluminum ladle, lead ladle, steel slag etc. Generally the outer surface temperature of the ladle is 200-300 degree , due to the high temperature, the cart should be designed with heat exposure proof

.jpg)

12.5.1.3 Iron Preparation Hot Metal Desulfurization - Sulfur in the molten iron is sometimes reduced before charging into the steelmaking furnace by adding reagents. The reaction forms a floating slag which can be skimmed off. Desulfurization may be performed in the hot metal transfer (torpedo) car at a location between the blast furnace and

.jpg)

How Steel Is Made. Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides. The first blast furnaces appeared in the 14th century and produced one ton per day. Even though equipment is improved and higher production rates can be achieved

.jpg)

Feb 13, 2015 · 106 reduction in vehicle weight can improve fuel efficiency by 6%–8% for conventional internal combustion 107 engines, or increase the range of a battery-electric vehicle by up to 10%.10 A 10% reduction in the weight 108 of all vehicles in the U.S. car and light-duty truck fleet could result in a 1,060 TBTU annual reduction in

.jpg)

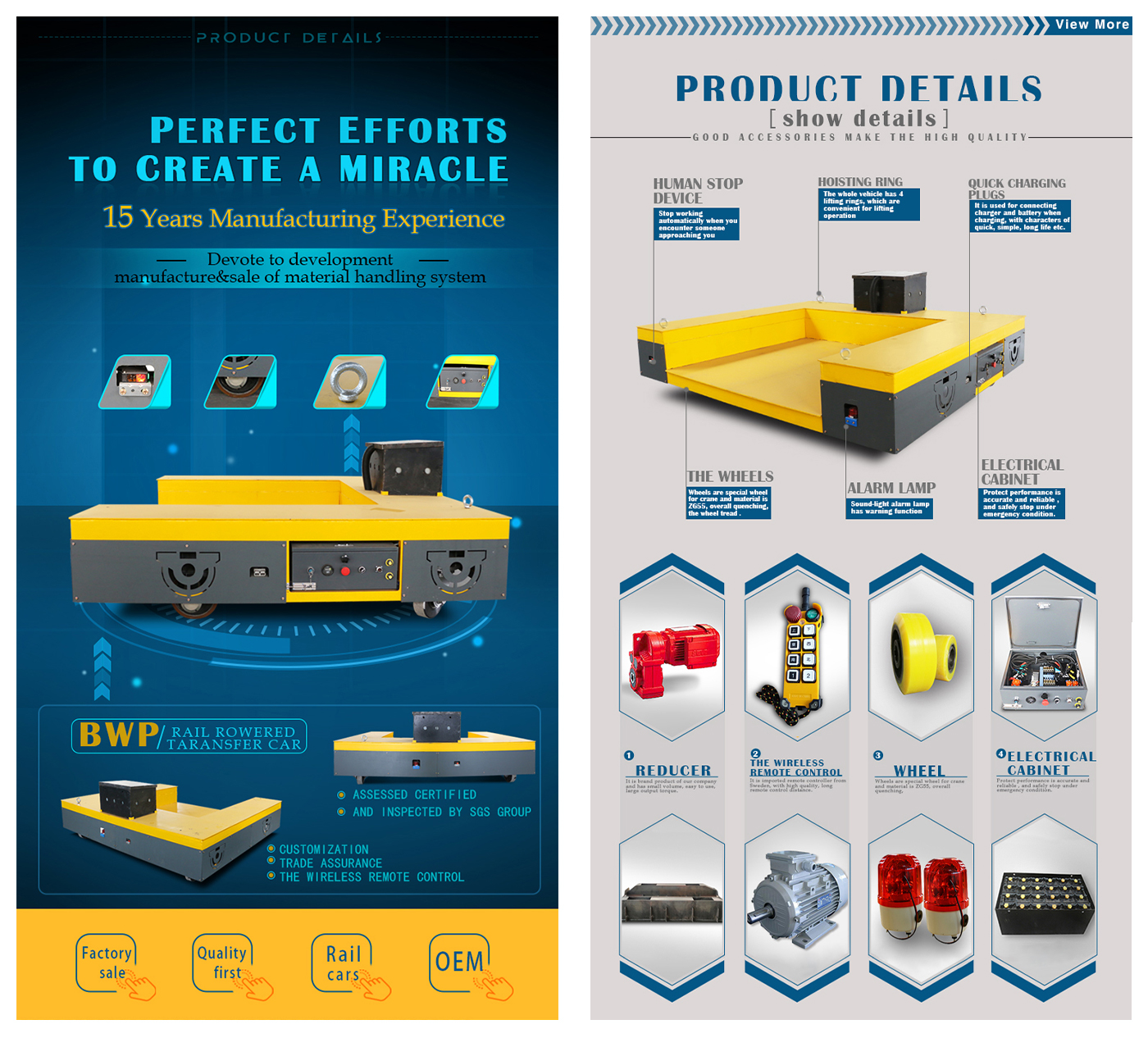

Henan Perfect Handling Equipment Co.,Perfect Transfer Cart, Experts in Manufacturing and Exporting Handling Equipment, Transfer Cart and 2975 more Products.

.jpg)

Open Throat Feature on the 25-ton press provides additional work area by mounting the cylinder on the outside for C-frame advantage. Frames Can Be Used Horizontally for pressing jobs on extra-long shafts. Electric, Air Or Hand Hydraulic Pumps are available. All are standard Power Team pumps. CE Rated electric

.jpg)

scrap. The primary source of post-consumer scrap is the automobile, and in 2004, the steel industry recycled 14.2 million tons of iron and steel scrap from 14 million vehicles. 12.5.1.2 Process Description In a minimill, scrap metal is melted and refined in an electric arc furnace (EAF) to make steel products.

.jpg)

Dec 03, 2012 · The reason that electric vehicles may actually decrease utility rates lies in daily oscillations in power consumption. Electric vehicles typically charge at night, when electricity is cheapest to 11 California Electric Transportation Coalition. (2012). Plug-in Electric Vehicle Deployment in California: An Economic Jobs Assessment. Retrieved

.jpg)

Electric Motor-driven, Pendant-controlled. This 50-metric ton capacity coil transfer car can transport two 25-metric ton coils. Replaceable wear pads protect the coil surface. The operator walks along with car, operating it from a hand-held pendant. Battery Powered. This 20,000-pound capacity transfer car is used to move stamping dies.

.jpg)

Energy use in the steel industry The steel industry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmental impacts, such as greenhouse gas emissions. Steel is also essential for energy production and transmission.

.jpg)

The steel industry actively manages the use of energy. Energy conservation in steelmaking is crucial to ensure the competitiveness of the industry and to minimise environmental impacts, such as greenhouse gas emissions. Steel saves energy over its many life cycles through its 100% recyclability, durability and lightweight potential.