.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

A self-unloading train for the transfer of bulk commodities having a plurality of hopper cars coupled together, a train conveyor having an endless belt supported on the hopper cars in a position so as to receive material discharged from the hopper cars, and a conveyor

spillage at transfer points, friction in long chutes, as well as problems of wear and maintenance access. 2. INTRODUCTION Considerable time and money is spent fixing up conveyor chutes on site. Engineering expertise must be a blend of basic knowledge and

Esskay Material Handling Equipments & Systems - Offering Movable Steel Transfer Car Weighing System, For Molten Metal Transportation, Ladle Capacity: up to 400 tons at Rs 300000/piece in Bengaluru, Karnataka. Read about company. Get contact details and

12/9/2018 · Save time with the advanced, unloading belt conveyor system that ensures gentle and efficient seed delivery directly into your air seeder. The six compartment, stainless steel tank is designed to transport seed and fertilizer simultaneously without damage or cross-contamination. At an unload rate of 2 tons/min, unloading is reduced to 1550

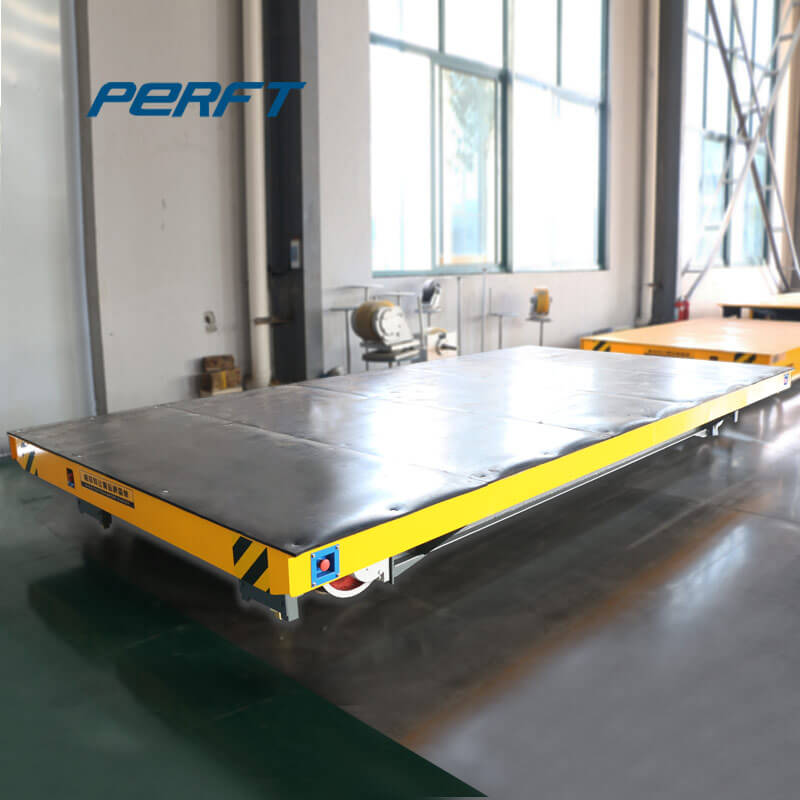

The transfer car is powered by maintenance free battery, which is installed in the cars, the battery conduct the power to the dc motor by the electrical control system. The transfer car can start, stop, go forward, backward, etc. by this principle. Main Feature: 1.Capacity up to 1,000 tons. 2.Maintenance Free Battery (Reducing maintenance)

Our Expertise as Aggregate Conveyor Specialists. Kemper Equipment specializes in custom-designed, automated aggregate conveyor systems that bring numerous cost savings—and safety benefits—to aggregate mining operations. We've been helping quarries, mining operations, and asphalt companies improve efficiency, save money, and move product

the stacking machine from one stockpile bed to other through transfer car arrangement. To cater for these different functions and end uses, various types of rail mounted stackers maybe used. A number of different design concepts may be developed for stacking

Semi-pneu 10″ wheels reduce effort to position conveyor. High capacity 12″ or 16″ belt delivers up to 90 tons* per hour. Choice of self-powered with 3 hp motor; or auxiliary powered by tubular conveyor with efficient Quick-Tatch option. Handles up to 70 tons

46 Figure 46-1 Bulk materials, such as those shown in Table 47-1, can be conveyed pneually using a Radial Blade or Material Transfer Blower. You can calculate your system’s fan or blower requirements by following the steps in Figure 48-1. In the following

Machinable Easy-AccessBase-Mounted Shaft Supports. Create a support that fits the exact dimensions of your shaft. Good for use with square- and hex-profile shafts, these aluminum supports also work with round shafts of any diameter up to 1". Use them for light-to-medium-load linear motion applications where shaft alignment is not critical.

Coal conveyor C-1 carries the coal from under the dumper into the top of the enclosed central transfer house and drops onto either conveyor C-2 or C-51. Controlled Flow Transfer Chute (CFTC) technology is used at these drops designated TP-03 and TP-04

Conveyors Orlando Office Number 407-859-8750 Conveyor Systems Orlando Easy Material Movement Conveyors are an incredibly efficient tool for moving materials throughout a warehouse or manufacturing facility. While there are many different types of conveyors – typically they use a belt, a chain, a series of rollers, or some combination of the three to move goods Conveyors Read More »

A slackless drawbar system allows the DumpTrain® to negotiate curves with ease. Plus it’s built to be light weight at only 63,000 pounds per hopper car (263,000 pounds fully loaded), and 186,000 pounds for the transfer car so it can be maneuvered quickly to

Lift & Transfer in a VeraMove Ultra A timing belt lift & transfer in a VersaMove Ultra, SRF-P 2012 conveyor. GUF-P 2000 Hopper Conveyor Conveyor with Guarding mk is able to supply conveyors equipped with custom guarding for your specific needs.

In an auto conveyor system, a plurality of independently operable carrier or transport structures are interconnected in closed loop configuration. Each carrier includes plural sheets of overlapping slats, each supported by a carriage which allows the slat to pivot