.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Feb 20, 2022 · According to Mike Schafer's book, "Freight Train Cars," some rocks weighed as heavy as 60-65 tons and the railroad employed timber-planked cars on four wheels (two axles resembling wagon wheels) to handle them. After common-carrier systems began service a few years later, beginning with the Baltimore & Ohio, more sophistication took root.

BENEFITS. Long-Term Reliability – Macton locomotive sanding systems have been in service for decades and move smoothly and quietly day in and day out for years – in fact, to our knowledge, none of these systems has ever failed to operate within the specified design criteria where proper minimal maintenance was performed.

Situated south of the Island of Bahrain, the project is a major resort comprising islands that have been developed as reclaimed land and designed in fantasy shapes. The bridges require the manufacture of precast post-tensioned deck elements, each 16,2 metres long and 200 tons in weight.

115RE Rail. 115RE rail has a standard profile according to AREMA. Its nominal weight is 56.9kg/m. As a type of heavy rail, it is mainly used for mining tracks since its high strength. 115RE rail is heat-treated to control the hardness and strength of the steel. 115RE rail has better performances in hardness, strength, wear-resistance, and corrosion resistance than many other railroad tracks.

• Rail Car Unloading • Storage Silos, Day Hoppers Polypropylene 0.25 to 0.30 lbs./inch/mil ... to roll transfer by an auto cut and

Can drive machinery directly on to the car: Open Design: Ability to load/unload from several different positions: Wood or Steel Floors: Nail blocking and bracing to the floor for a damage-free, secure shipment: Length of Car: 60 and 89 ft. Gross Weight on Rail: Range from 250,000 to 286,000 lbs. Load Limit: Range from 147,000 to 202,000 lbs.

Benzene emissions from benzene transfer operations. Unless exempted, the total of all loading racks at which benzene is loaded into tank trucks, rail cars, or marine vessels at each benzene production facility and each bulk terminal. (Subpart BB) n. Benzene waste operations.

What is Polypropylene (PP), and What is it Used For? Polypropylene (PP) is a thermoplastic “addition polymer” made from the combination of propylene monomers. It is used in a variety of applications to include packaging for consumer products, plastic parts for various industries including the automotive industry, special devices like living hinges, and textiles.

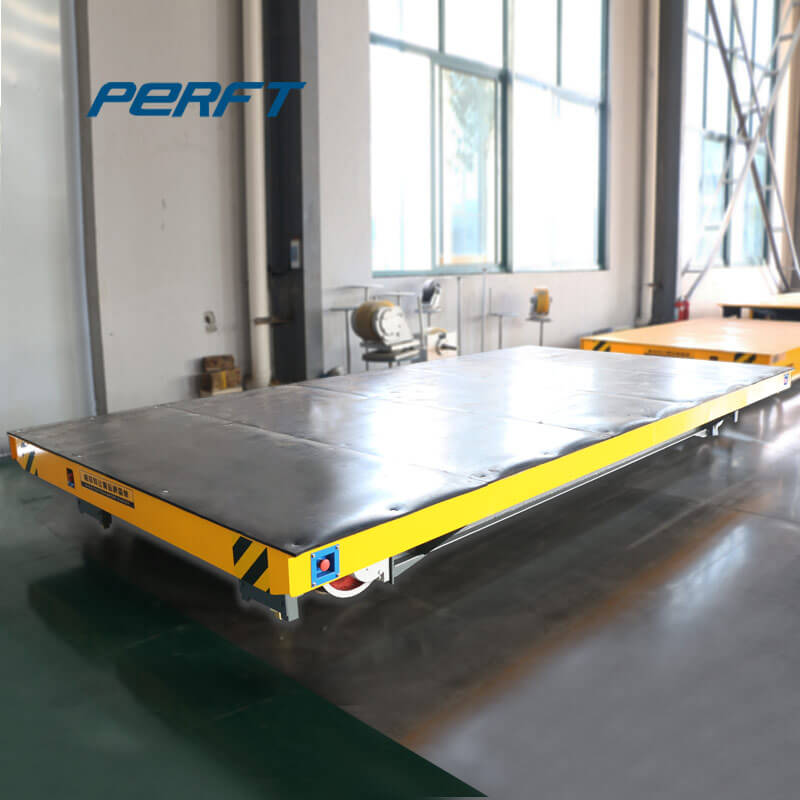

coil transfer carts quote 1-300 ton-Perfect Coil Transfer TrolleyShopping Cart & Ecommerce Software - 1ShoppingCart.comProviding innovative eCommerce products for more than a deca

independent of a transport vehicle. No trailer damage! So, use lighter weight transport equipment to achieve greater payloads. SSI COMPACTORS OFFER: Pre-formed payloads of 20 to 40 tons Compaction forces from 200 to 400 tons MSW compaction density to 1,200 pounds per cubic yard Throughput rates from 25 to 140 tons per hour

"B" Kit (ton containers) 1 "C" Kit (rail cars) 1 Transfer equipment for railcar (pump or compressor, hoses, fittings and power) 1 set Transfer equipment for one ton containers and cylinders (pig tails) 1 Chlorine detector 1 Nitrogen cylinders with regulator and hoses. 1 set Gaskets (viton; within service date) 1 set

PU - polyurethane on cast iron, WED-polypropylene, CI-cast iron • Please note: Spigot length 150mm • Please specify spigot or socket diameter when placing order FG SERIES SCAFFOLDING CASTORS 100 200FG100 PUP 32A32 150 400FG150 PUP 35A35/38 200 400FG200 PUP 35A35/38 ADING kg 200-400 Available with 32mm spigot, 35mm spigot, 38mm spigot

Apr 28, 2021 · Applying the Step 2 calculation to data developed by the USDA Forest Service for the Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2018 yields a result of 200 metric tons of carbon per hectare (or 81 metric tons of carbon per acre) for the carbon stock density of U.S. forests in 2018, with an annual net change in carbon stock per

Transfer piping between the silo and the processing machines should optimally run no more than 200 feet to 300 feet. Keeping to that mea-sure may mean much longer lengths of transfer piping on the front end from the unload-ing area to the storage silo. One mistake often made in the design of a transfer system is not allowing enough

Polypropylene has a melting point of 266F to 340F (130C to 171C). Polypropylene, along with other plastic resins in powder, flake, or pellet form, is typically shipped via dry bulk trucks or hopper rail cars. Approximately 90% of plastic resins in North America leave the producing plants in covered hopper cars.