.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Apr 30, 2021 · Whiting Services Detroit was engaged to perform TrackRunnerTM Surveys on two Whiting cranes that are over 70 years old. These cranes are used as intake cranes to operate and adjust the water levels in the various locks that allowPerfect cargo freighters to move between multiple water-ways. Our WSI service technicians performed the TrackRunnerTM Surveys []

• Converter Changing Rail Carrier, Payload 170 Ton, Speed 10 M/Min, Hydr. Lift. • Steel and Slag Rail-Carrier, Load 190 Ton, Speed 25M • Slag Rail-Carrier • Converter Lining Stand: Break-Out Stand and Converter Tilting Stand 6 For more information, please call Hilco Industrial at +31 20 470 0989

Our quality: 1. The raw material procurement process is strict and has been inspected by quality inspectors. 2. The materials used are all steel products from major steel mills, and the quality is guaranteed.3. Strictly code into inventory. Other suppliers: 1. Cut corners, such as: originally used 8MM steel plate, but used 6MM for customers. 2.

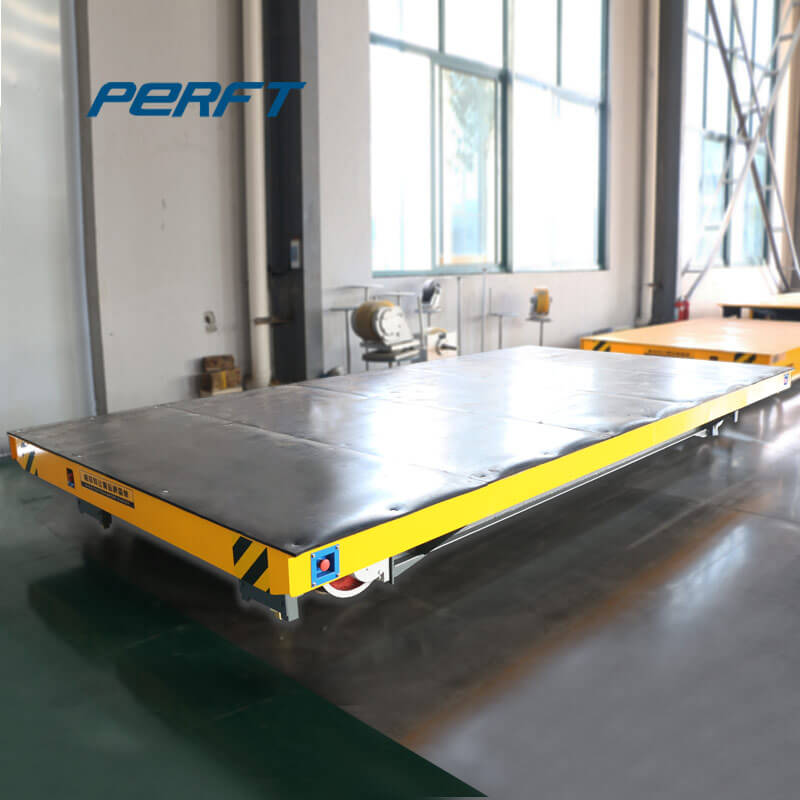

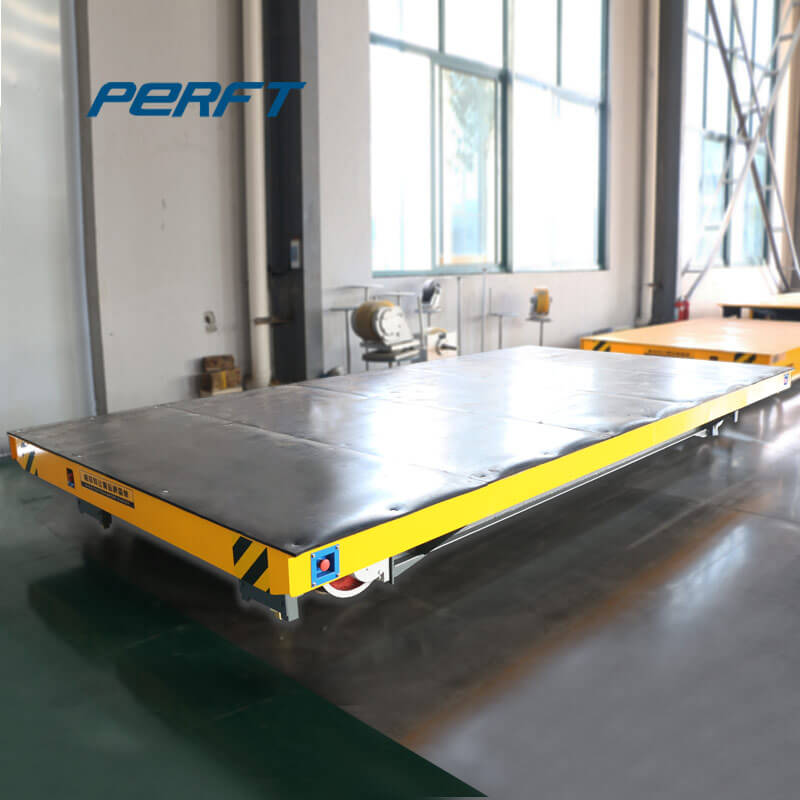

Electric transfer cart is a sort of rail guided material transport cart powered by the cable reel. It is used to handle and move a variety of materials, such as dies, industrial pipes, coils, heavy equipment and components. This transfer cart on rails can be designed withPerfect load capacity, ranging from 2 tons to over 150 tons. We also provide tailor-made electric rail transfer cart to suit your specific load handling

Description of Business. Norfolk Southern Corporation (NYSE: NSC) is one of the nation’s premier transportation companies. Its Norfolk Southern Railway Company subsidiary operates approximately 19,300 route miles in 22 states and the District of Columbia, serves every major container port in the eastern United States, and provides efficient

Basic 200-Ton 4-Truck Hot Metal Bottle Car - Kit -- With End Cones - Undecorated 661-710 661-710

Basic oxygen steelmaking (BOS, BOP, BOF, or OSM), also known as Linz-Donawitz steelmaking or the oxygen converter process is a method of primary steelmaking in which carbon-rich molten pig iron is made into steel.Blowing oxygen through molten pig iron lowers the carbon content of the alloy and changes it into low-carbon steel.The process is known as basic because fluxes of burnt lime or

Jul 14, 2021 · Construction on the state-of-the art, ½-mile long rail building will employ about 800 construction workers and use 7,000 tons of steel, 52,000 yards

mill is shown in Figure 9.9.1-2. Wheat arrives at a mill and, after preliminary cleaning, is conveyed to storage bins. As grain is needed for milling, it is withdrawn and conveyed to the mill area where it first enters a separator (a vibrating screen), then, an aspirator to remove dust and lighter impurities, and then

37. 200 ton hot metal bottle car the modern mixer type ladle car is better known as a submarine or sub, torpedo or bottle car. They come in 12, 16 and 24 wheel versions to support the weight of refractor-lined vessel and 80 to 225 tons of molten steel. 38. Hot metal ladle car is equipped with wings for pig machine service, so a crane can lift

The American steel industry is committed to manufacturing innovative products and implementing processes that achieve environmental, social and economic sustainability. The American steel industry is the cleanest and most energy-efficient of the sevenPerfectst steel producing countries in the world. Steel Industry Sustainability PDF Download >>

The hydraulic dumping rail transfer trailer is applied to transfer cargoes of steel tubes and pipes, steel coils, galvanized coils, mills, steel plates and sheets in production assembly lines, material delivery, stock transfer, coal and oil industry, metallurgy plant, shipbuilding industry, machine manufacturing industry.

In 1994, with 2 integrated steel mills (at Cleveland and Indiana Harbor, IN), Cleveland's only remaining integrated producer ranked as the nation's 3rd-largest steelmaker and 2nd-largest producer of flat-rolled steel. Working at 99% capacity, the Cleveland Works in 1994 produced 4.8 million tons of raw steel.

This fully automated coil transfer car is track mounted. It was designed to move steel coils weighing 42 tons and to handle coils up to a maximum diameter of 80 inches and a maximum width of 72 inches. Tow Type. Fabricated of welded steel, this towable die cart is a flexible addition to your operation.

We offer AQ-KP series electric transfer cart that runs on rail and trackless transfer cart to meet your precise requirements. AQ-KPD rail transfer cart; Load capacity: 2-150t; power source: rail; application: fabrication shops, steel plants, warehouses, chemical plants, etc. This type of material handling cart is powered by the rails. It is ideal for heavy load, high frequency of use and long distance transportation